FLAT AND CURVED TEMPERED GLASS

It involves heating and cooling stages on a horizontal line to impart compressive stress to the outer surfaces of the glass and an indirect tensile stress to the center of the glass. It increases the durability and resistance to thermal stresses of the glass. It does not change the volume, chemical structure, color and clarity of the products. Tempered glass is 5 times more resistant to impact than non-heat-treated glass. It is suitable for use as safety glass as it reduces the risk of injury by breaking into small and blunt pieces when broken. Flat and curved tempering process is performed in our factory.

PRODUCT FEATURES

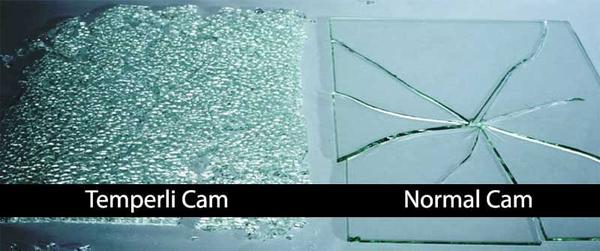

– While normal glass can shatter into sharp particles after breakage and cause injury, tempered glass shatters into small and blunt pieces when broken. Therefore, the risk of injury is minimized.

– It is 4-5 times more durable than original glass.

– It has good thermal resistance and can withstand temperature differences.

– Tempered glass can withstand a thermal shock of 300°C, while untempered glass can break when subjected to a thermal shock of about 40°C.

– It also has increased thermal shock resistance and can withstand temperature changes up to 150 ~ 200°C.

– After the glass becomes tempered glass, cutting, grinding and chip removal operations cannot be performed on it. Heat treatments do not change the volume, color, clarity and chemical structure of the glass.

Areas of Use

Tempered Glass is widely used in buildings, interior and exterior facades, furniture industry, durable consumer goods industry (such as refrigerators, ovens, kitchen hoods), lighting industry, automotive industry, ship and air transportation vehicles and many other areas.

As Adana Cam, we continue our journey, which started in 1995 in a 400 m² area in İstiklal Neighborhood in Adana, in 2011 in our new factory in a closed area of 7500 m² on Ceyhan Road 3.km. Our company, which initially sells wholesale glass to Adana and its districts, has added the

© All Rights Reserved. Design Coding. M2K DIGITAL